Trenching for Armoured Cable (SWA) in Ground Solar Installation

Proper trenching for armoured cables is vital when installing a ground solar installation, ensuring reliable electrical connections, safety, and compliance with regulations. Steel Wire Armoured (SWA) or duct-grade cables are ideal for such installations as they are designed to withstand environmental stresses and mechanical impacts. However, adhering to strict guidelines is essential for achieving long-term durability and functionality in solar farms.

Ground Solar Installation compliance and safety rules for underground cabling

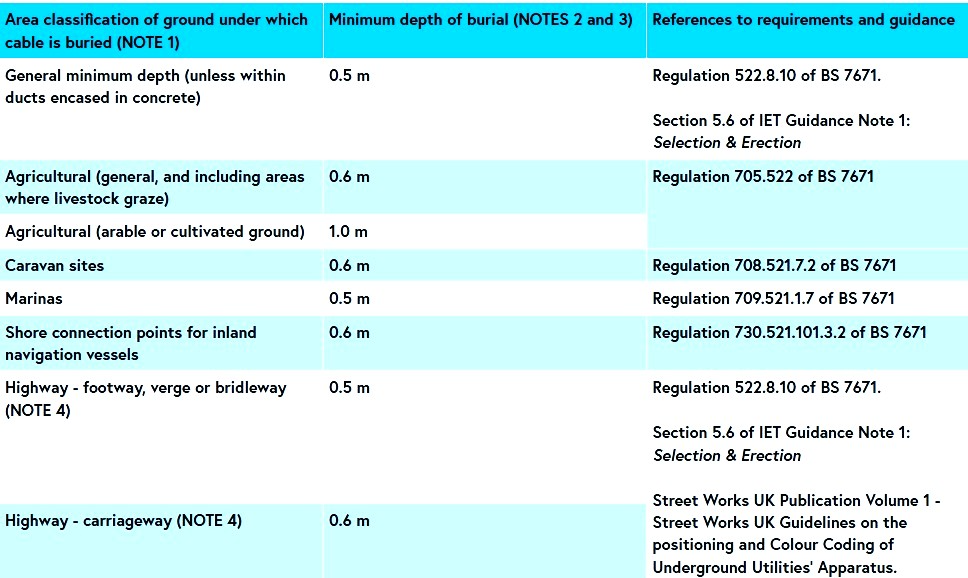

To meet the requirements of the IET Wiring Regulations (BS7671:2018+A2:2022) and other applicable standards, the following must be considered when laying cables in solar panel farms:

Protection Against Mechanical Damage

Regulation 522.8.10 requires cables buried in the ground to incorporate earthed armour or a metal sheath. This protective layer ensures that cables are not damaged by external forces unless installed within conduits or ducts offering equivalent protection.

Marker Tape or Cable Covers

All buried cables in ground mounted solar farms must be clearly marked with marker tape or covers positioned above the cable. This helps prevent accidental damage during future excavation or maintenance work.

Depth Requirements

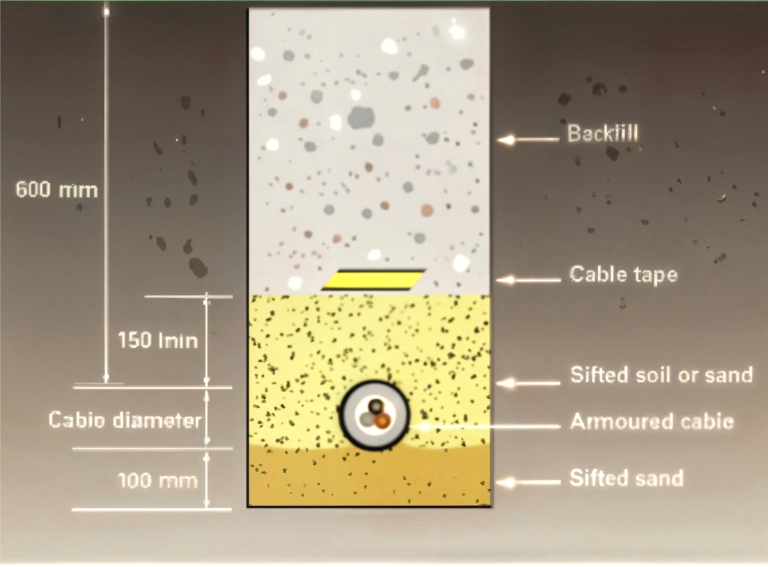

The cables must be buried deep enough to avoid disturbances caused by equipment such as tractors, maintenance machinery, or ploughing. A recommended burial depth of 600 mm from the ground surface to the top of the cable provides a practical guideline, ensuring the cable remains undisturbed during routine farm activities.

Recommended Trenching Depths for Solar Panel Farms

The IET Guidance Note 1 outlines depth recommendations to protect cables in solar farm installations:

Minimum Depth:

A depth of 600 mm is recommended for installations that do not meet highway construction standards.

Soft Ground:

Increase the depth by 400 mm in soft or unstable soils to prevent damage from compression, frost heave, or settling.

Vehicle Compression:

Deeper burial may be required in areas where heavy vehicles or machinery frequently operate to prevent accidental cable damage.

Ground Solar Installation Location- Specific Considerations

Ground solar panel installation often spans diverse environments, each with unique trenching requirements:

Agricultural and Cultivated Land:

✅ Minimum burial depth: 600 mm.

✅ For areas subject to frequent ploughing or tilling, increase the depth to 1,000 mm.

Hardstanding or Vehicle Access Areas:

✅ Where solar farms overlap with access roads or parking areas, deeper burial ensures cables remain protected from heavy machinery and vehicular loads.

Unstable or Wet Soils:

✅ In wet or soft soil conditions, the trench depth must account for ground compression and frost heave by adding an additional 400 mm to the standard depth.

Preparing Trenches for Solar Panel Farms

Follow these steps to ensure safe and compliant cable trenching for solar panel farms:

1. Excavation

Dig the trench to the required depth based on the environment and soil conditions. Ensure the width is sufficient to accommodate both the cable and protective layers.

2. Base Layer

Line the bottom of the trench with sifted sand or fine soil to create a cushioning layer, protecting cables from damage caused by sharp rocks or uneven ground.

3. Cable Placement

Lay the SWA cable carefully, avoiding strain or bends beyond the manufacturer’s recommended radius.

4. Marker Tape or Covers

Install marker tape 150 mm above the cable to provide a clear warning for future excavators.

5. Backfilling

Cover the cable with sifted sand or fine soil before filling the trench with the original soil. Compact the soil gently to secure the cable in place.

Importance of Proper Trenching in Ground Solar Installation

In ground mounted solar panel systems, improper trenching can lead to:

Cable Damage:

Shallow burial exposes cables to damage from machinery or natural ground movements.

Operational Failures:

Damaged cables can lead to system interruptions, affecting the efficiency and reliability of the solar installation.

Safety Hazards:

Poorly installed cables increase the risk of electric shock or fire.

Costly Repairs:

Non-compliance with regulations can result in penalties and expensive remedial work.

Conclusion

Proper trenching for armoured cables in ground mounted solar panels is essential for achieving safe, reliable, and compliant installations. By following the depth guidelines, marking requirements, and preparation steps outlined above, you can ensure cables are well-protected from environmental and mechanical risks.

Given the unique challenges posed by diverse solar farm environments, consulting the IET Wiring Regulations and engaging experienced professionals are recommended for site-specific advice. Implementing these practices will safeguard the electrical infrastructure, ensuring the long-term success and sustainability of your solar panel farm.

Contact us today to learn how we can help you implement these practices and safeguard your ground mounted solar panel system infrastructure for years to come. Let’s power your solar farm’s future together!