Connecting Solar Panels: Series vs. Parallel in a Solar PV System

In the design and installation of a solar PV system, connecting solar panels correctly is fundamental to system efficiency, safety, and compatibility with system components such as string arrays, inverters and batteries. Solar PV panels (also known as photovoltaic panels or solar PV modules) can be wired in either series or parallel, or in a hybrid configuration combining both. Each approach impacts system voltage, current, and overall performance, so let’s break down the technical details to guide proper configuration.

Series vs. Parallel: What’s the Difference?

In a photovoltaic (PV) system, the way solar panels are connected, in series or in parallel, and fundamentally affects how electricity flows through the system. This wiring choice determines not just the electrical characteristics of the solar array, but also its compatibility with inverters, charge controllers, and other system components.

The core trade-off is between voltage and current:

Series wiring increases the total voltage of the array while maintaining the same current as a single panel. This is typically used to meet the input voltage requirements of string inverters or to reduce voltage drop over long distances.

Parallel wiring increases the total current while keeping the voltage consistent with a single panel. This approach is often chosen for battery-based or off-grid systems where higher current is required and lower voltage operation is acceptable.

Appreciating these differences is crucial when creating a solar PV system designed for specific project goals, whether it’s increasing energy yield, ensuring inverter compatibility, or maintaining performance under partial shading.

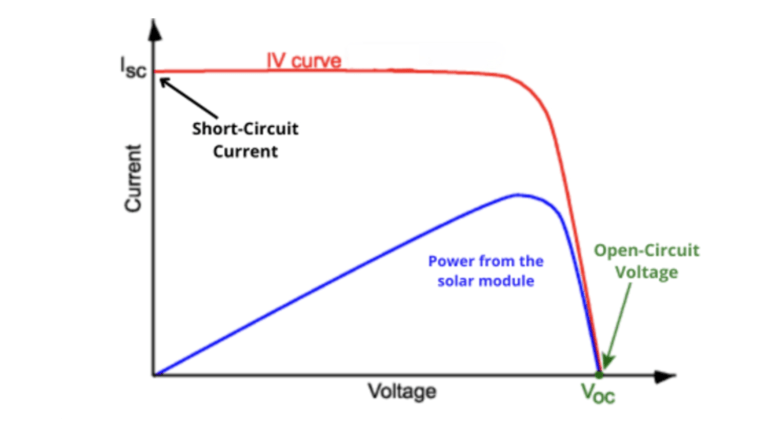

Analysing Open-Circuit Voltage (Voc) and Short-Circuit Current (Isc) in Solar Panels

When evaluating solar PV modules, whether for purchase, installation, or system design; two of the most fundamental electrical characteristics are Open-Circuit Voltage (Voc) and Short-Circuit Current (Isc).

These specifications aren’t just numbers on a datasheet, they are critical to system safety, performance, and long-term reliability.

Voc is the peak voltage a solar panel can produce when it is not connected to any load, essentially, when the circuit is open. You can measure this by using a voltmeter across the panel’s positive and negative terminals with no current flowing.

Importantly, Voc is always measured under Standard Test Conditions (STC), which assume a cell temperature of 25°C, solar irradiance of 1000 W/m², and an air mass (AM) of 1.5. These idealised lab conditions provide a consistent baseline for comparing panels but may differ from real-world performance.

What is Open-Circuit Voltage (Voc)

When connecting multiple solar panels in series, their voltages add up. This cumulative voltage must remain within the input voltage range of your inverter or charge controller. Exceeding this threshold isn’t just inefficient it can damage your equipment or drastically reduce its operational life.

In practice, the best time to measure Voc is early in the morning. Panels are typically coolest just after sunrise, and cooler temperatures result in higher voltage output. This is especially important in colder climates, where extreme Voc values could push a system beyond its designed voltage limit.

Why is Voc Important?

What is Short-Circuit Current (Isc)?

Isc refers to the current generated by the panel when its output terminals are directly connected with no external load, essentially, a short circuit. It’s the largest current the panel can deliver under STC (standard testing conditions), and it’s typically measured by wiring an ammeter in series between the positive and negative terminals.

Although measuring Isc is generally safe for the panel, it must be done with caution. High current flow, even momentarily, can cause arcing or damage to poorly connected terminals. Always use insulated tools and appropriate personal protective equipment.

Isc gives a clear picture of the panel’s current output limit, which is vital when designing parallel PV string configurations. In such setups, current adds up across strings, so knowing your Isc helps you size wiring, fuses, and protection devices correctly. It also plays a role in system diagnostics and performance monitoring.

Why does Isc matter?

Final Voc and Isc Thoughts

Both Voc and Isc are foundational parameters in any photovoltaic system design. Misjudging either can lead to system inefficiencies or premature component failure. By interpreting and correctly applying these values, solar professionals can ensure system integrity, accentuate performance, and avoid costly oversights.

Whether you’re an installer, designer, or facility manager, keeping these figures front of mind will help you build systems that are not only compliant but also reliable, safe, and future-ready.

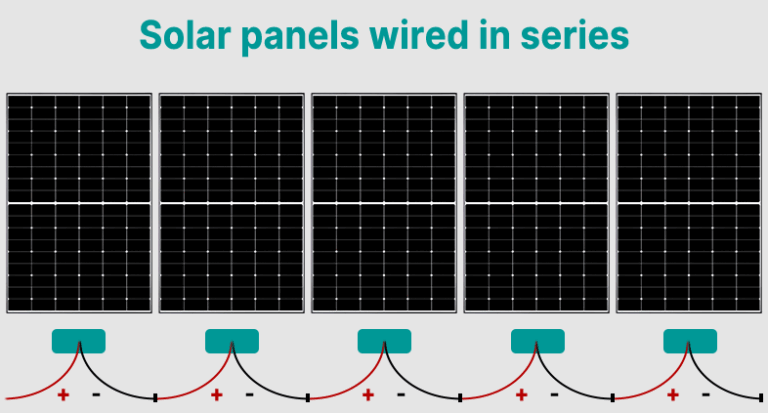

Series Connections: Increasing Voltage

Series wiring is one of the most common configurations used in solar PV systems, particularly in grid-tied commercial and industrial applications. This method connects the positive terminal of one solar panel to the negative terminal of the next, creating a single, continuous electrical loop known as a string.

This configuration adds the voltage of each panel together while keeping the current the same as that of a single panel. For example, wiring ten 40V solar PV modules in series results in a combined output of 400V, ideal for systems requiring high-voltage inputs, such as central inverters or long cable runs to the inverter location.

Series connections are a practical and efficient way to design solar arrays that meet the voltage thresholds of inverters, reduce resistive losses over distance, and simplify cable management. However, they require careful string design to avoid performance losses due to shading or mismatched panels.

Example:

10 × 400W panels (each with Open Circuit Voltage (VOC) 40Volts, 10A)

✅ Voltage: 10 × 40V = 400V

✅ Current: 10A

✅ Total Power: 400V × 10A = 4,000W

Key Characteristics

✅ Voltage increases

✅ Current remains the same as one panel

All power flows through a single path

Advantages

✅ Ideal for systems requiring high voltage, such as grid-tied inverters

✅ Lower current means smaller and more affordable cabling

✅ Reduced losses over long wire runs, improving efficiency

✅ Good match for high-voltage inverter input requirements

Disadvantages

✅ Shading or soiling on one panel affects the entire string’s output

✅ High voltage can pose additional safety risks if not properly managed

Best Use Cases

✅ Commercial or industrial solar installations with long cable runs

✅ Systems using centralised string inverters

✅ Situations requiring fewer components (e.g., no need for combiner boxes)

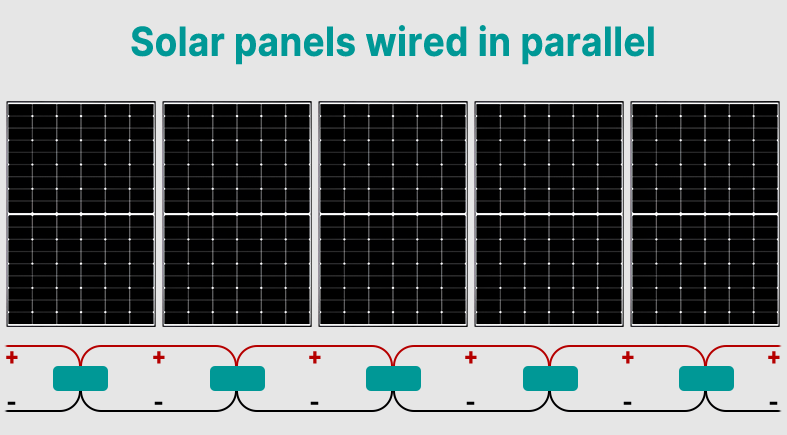

Parallel Connections: Increasing Current

Parallel wiring is the go-to configuration when a solar PV system needs to deliver higher current at a fixed voltage. In this setup, all positive terminals are connected, and all negative terminals are connected, forming multiple electrical paths that feed into a common output.

This means each solar PV module operates independently, contributing its full current to the system without altering the overall voltage. The result is a configuration where system voltage remains the same as that of a single module, while total current increases in proportion to the number of panels.

Parallel configurations are especially useful in low-voltage applications, such as battery charging or off-grid systems, where consistent voltage and increased current flow are essential. One of the key advantages is fault tolerance, if one panel is shaded or underperforming, the impact on the overall system is nominal compared to series wiring.

However, higher current comes with its own considerations. Larger wire sizes, higher-rated overcurrent protection devices, and increased installation costs must be factored in during system design.

Example:

10 × 400W panels (each 40V, 10A)

✅ Voltage: 40V

✅ Current: 10 × 10A = 100A

✅ Total Power: 40V × 100A = 4,000W

Key Characteristics

✅ Voltage remains constant

✅ Current increases

✅ Each panel contributes its own current to the system

Advantages

✅ Shading on one panel has less impact on the system’s total output

✅ Suited for applications where voltage limitations are a concern

✅ Ideal for off-grid or battery-based systems that require higher current

Disadvantages

Best Use Cases

Series-Parallel (Hybrid) Configurations

In many real-world solar PV installations, particularly in commercial, industrial, or large-scale systems, a simple series or parallel configuration alone may not deliver the ideal balance of voltage, current, and system flexibility. That’s where a series-parallel (hybrid) configuration comes into play.

This method involves grouping panels in series strings to increase voltage, then connecting those strings in parallel to boost current. By combining the strengths of both wiring methods, installers can fine-tune the system to meet the specific electrical requirements of the inverter or battery bank, while also addressing factors like partial shading, equipment limitations, and installation cost-efficiency.

This approach is especially effective when working with multi-MPPT inverters, large DC-coupled storage systems, or when the site layout demands a mix of panel orientations and conditions. It provides the design flexibility to prioritise both performance and hardware compatibility across varying environmental and load conditions.

Example Hybrid:

A series-parallel layout gives you the best of both worlds, stable voltage, increased current, and greater resilience to shading, making it the preferred configuration for many complex orientation of solar PV systems.

Choosing the Right Wiring Configuration

The way you wire your solar PV panels; in series, parallel, or a combination of both, has a direct impact on system performance, efficiency, and cost. Your choice should align with key technical factors such as inverter voltage requirements, battery integration, shading conditions, and cable run distances.

Series connections are best for high-voltage systems and long cable runs, offering lower current and reduced wiring costs. Parallel connections, by contrast, are better for low-voltage applications like battery charging and provide greater shading resilience but may require thicker, more expensive cabling.

The table below breaks down the most important considerations when connecting solar panels in different configurations:

Factor | Series | Parallel |

Inverter voltage requirements | ✔ High voltage input systems | ✘ May not meet minimum voltage |

Battery charging | ✘ Not optimal | ✔ Ideal for current-demanding loads |

Shading impact | ✘ One panel affects all | ✔ Limited to individual panel impact |

Wiring cost | ✔ Smaller wire size = lower cost | ✘ Thicker wires = higher cost |

Distance to inverter/controller | ✔ Less loss over distance | ✘ Greater loss due to high current |

Final Connecting Solar Panel Thoughts

Whether you’re working on a small-scale residential array or a large commercial solar installation, gaining insight into how to wire your solar PV modules in series, parallel, or both is essential. Each configuration offers distinct benefits and limitations depending on your voltage needs, inverter compatibility, shading conditions, and installation budget.

Proper planning when connecting solar panels not only improves performance but also ensures safety, efficiency, and long-term reliability of the system. As the solar industry evolves, smart configuration choices remain a cornerstone of successful solar energy deployment, whether it’s for offices, industrial units or expansive solar farms.

If you’re designing a solar PV system or assessing an existing setup, make sure your string layout matches your electrical and performance goals. It’s a detail that can make or break your return on investment.

Ready to perfect your commercial solar investment with expert system design and installation? Contact Excel Energy today to discuss the ideal solar PV configuration for your business needs. Let us magnify your energy efficiency, reduce costs, and future-proof your operations with reliable, bespoke-built solar solutions.